Our cylinders are designed by CAD or 3D, and have been through ISO9001:2000 international quality system certification.

Our production is managed according to ERP. These factors ensure our quality to be the top in China. Warranty period for our cylinder is 2 years. For some special cylinders, the period is 5 years. All the drawings, records of production and inspection would be kept for 10 years.

Our production is managed according to ERP. These factors ensure our quality to be the top in China. Warranty period for our cylinder is 2 years. For some special cylinders, the period is 5 years. All the drawings, records of production and inspection would be kept for 10 years.

We choose accessories according to customers’ requirements. Usually, brands of seals can be PARKER, HALLITE or NOK, valves can be SUN or EATON, bearings can be LONGXI or SKF, displacement sensors are MTS or WALSH, and proximity switches are BALLUFF.

The delivery speed is fast; the average delivery time is 30-60 days. Sometimes only 2 weeks for special case.

Classifications can be DNV, ABS, LR, BV, GL, CCS, RINA, KR, NK, RS.

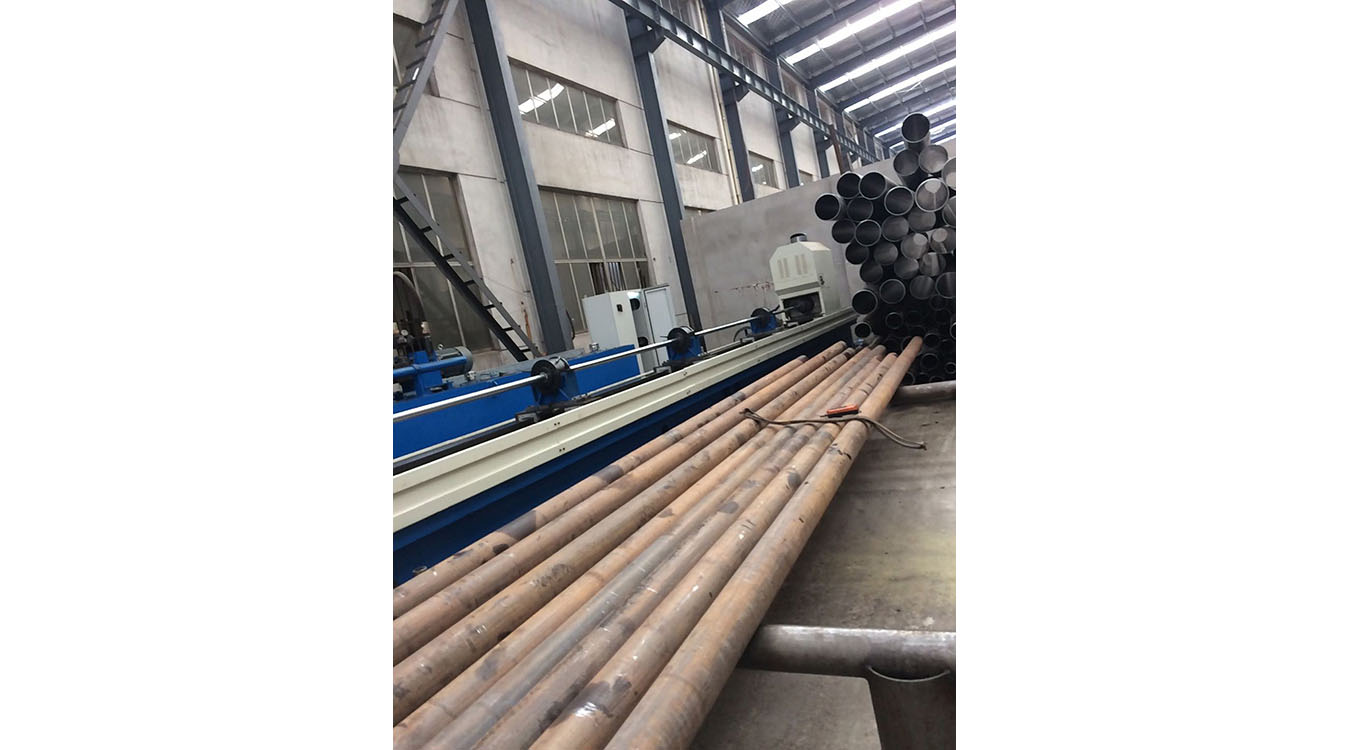

Our advanced producing equipments included DOSHAAN machine center, CNC Lather, TACHI scraping roller burnishing machine etc.

Welding technology certificates from GL and CCS.

High Precision: Honed Tube (Roughness of tube is 0.2μm and straightness is less than 0.15/1000), Piston Rod (Plating thickness is 10-100 micron. Surface roughness is 0.2μm and straightness is also less than 0.15/1000).

The purity of hydraulic oil is NAS 6-9.

The purity of hydraulic oil is NAS 6-9.